Optimizing Efficiency with Vial Tray Systems

- Max Hurst

- Jan 12

- 4 min read

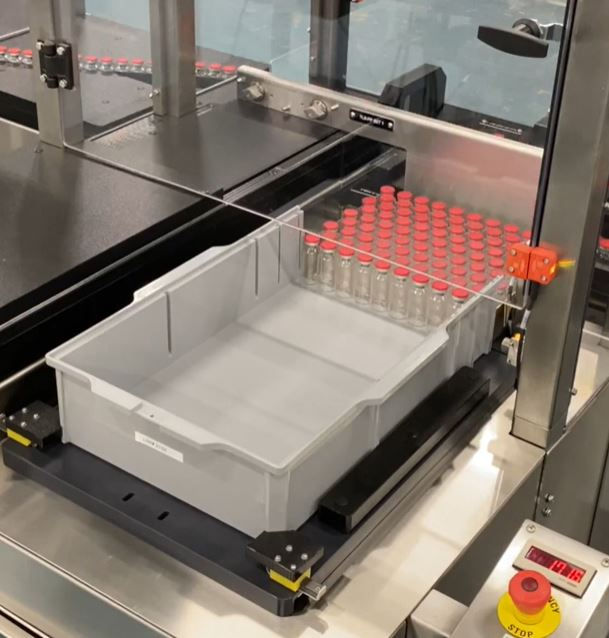

In pharmaceutical and biotech manufacturing, precision and efficiency are paramount. Every step in the production process must be optimized to ensure quality, safety, and productivity. One critical component often overlooked is the vial tray system. These systems play a vital role in organizing, transporting, and processing vials throughout manufacturing lines. By adopting efficient vial tray systems, companies can significantly enhance operational workflows, reduce errors, and maintain stringent quality standards.

The Importance of Efficient Vial Tray Systems in Manufacturing

Efficient vial tray systems are designed to streamline the handling of vials during various stages of production. These trays provide secure and organized storage, minimizing the risk of vial damage or contamination. They also facilitate automation by enabling smooth integration with robotic and conveyor systems.

Key benefits of efficient vial tray systems include:

Improved throughput: By reducing manual handling and organizing vials systematically, production lines can operate faster.

Enhanced safety: Secure trays prevent vial breakage and contamination, protecting both the product and personnel.

Consistency: Standardized trays ensure uniform vial positioning, which is essential for automated inspection and filling equipment.

Traceability: Some trays are designed to support barcoding or RFID tagging, aiding in tracking and quality control.

Implementing these systems requires careful consideration of vial size, material compatibility, and manufacturing line layout. Selecting the right tray design can lead to measurable improvements in efficiency and product integrity.

Key Features of Efficient Vial Tray Systems

To optimize efficiency, vial tray systems must incorporate several essential features. These features ensure that the trays meet the rigorous demands of pharmaceutical and biotech manufacturing environments.

Material and Durability

Trays must be constructed from materials that withstand repeated sterilization cycles, chemical exposure, and mechanical stress. Common materials include:

High-grade plastics: Resistant to chemicals and suitable for autoclaving.

Stainless steel: Durable and easy to clean, ideal for harsh environments.

Design and Compatibility

The tray design should accommodate the specific vial dimensions and shapes used in production. Features to consider:

Customizable cavities: To securely hold vials of various sizes.

Stackability: For efficient storage and transport.

Compatibility with automation: Trays should integrate seamlessly with robotic arms, conveyors, and inspection systems.

Cleanability and Compliance

Maintaining sterility is critical. Trays must be easy to clean and comply with regulatory standards such as FDA and GMP guidelines. Smooth surfaces and minimal crevices reduce contamination risks.

Traceability and Identification

Incorporating features like barcode slots or RFID tags enhances traceability. This capability supports batch tracking and quality assurance throughout the manufacturing process.

By focusing on these features, we can select vial tray systems that not only protect the product but also contribute to a more efficient and reliable manufacturing workflow.

Enhancing Workflow with Vial Tray Systems

Integrating efficient vial tray systems into production lines can transform workflow dynamics. Here are practical ways these systems improve operations:

Streamlined Loading and Unloading

Trays designed for easy loading and unloading reduce manual labor and handling time. This efficiency is especially valuable in high-volume production environments.

Automation Integration

Efficient vial tray systems are engineered to work with automated equipment. This integration enables:

Automated filling: Precise vial positioning ensures accurate filling.

Inspection and quality control: Consistent vial placement facilitates machine vision systems.

Transport and storage: Automated conveyors can move trays seamlessly between stations.

Space Optimization

Stackable and modular tray designs maximize storage space in cleanrooms and warehouses. This optimization reduces clutter and improves accessibility.

Error Reduction

By securely holding vials in place, trays minimize the risk of misalignment, breakage, or contamination. This reliability reduces costly production errors and downtime.

Implementing these systems requires collaboration between manufacturing engineers, quality assurance teams, and equipment suppliers. Together, we can tailor vial tray solutions that align with specific production goals and regulatory requirements.

Selecting the Right Vial Tray System for Your Facility

Choosing the appropriate vial tray system involves evaluating several factors to ensure compatibility and performance.

Assess Vial Specifications

Begin by cataloging vial sizes, shapes, and materials used in your processes. This information guides the selection of tray cavity dimensions and materials.

Evaluate Manufacturing Processes

Consider the stages where trays will be used, such as filling, inspection, or storage. Each stage may have unique requirements for tray design and material.

Prioritize Regulatory Compliance

Ensure that tray materials and designs meet industry standards for cleanliness, sterility, and safety. Documentation and validation support regulatory audits.

Consider Automation Needs

If your facility employs automation, select trays compatible with existing equipment or planned upgrades. This foresight prevents costly retrofits.

Review Supplier Capabilities

Partner with suppliers who offer customization, reliable delivery, and technical support. A trusted supplier can provide valuable insights and ongoing assistance.

By systematically addressing these factors, we can implement vial tray systems that enhance efficiency while maintaining compliance and quality.

Maximizing ROI with Efficient Vial Tray Systems

Investing in efficient vial tray systems yields significant returns beyond immediate operational improvements.

Reduced Product Loss

Secure trays minimize vial breakage and contamination, protecting valuable pharmaceutical products.

Lower Labor Costs

Automation-friendly trays reduce manual handling, allowing staff to focus on higher-value tasks.

Increased Throughput

Streamlined workflows and reduced downtime accelerate production cycles.

Enhanced Quality Control

Consistent vial positioning improves inspection accuracy, reducing defects and recalls.

Sustainability Benefits

Durable, reusable trays reduce waste compared to disposable alternatives, supporting environmental goals.

To maximize these benefits, we recommend conducting a thorough cost-benefit analysis and pilot testing tray systems before full-scale implementation.

Moving Forward with Advanced Vial Tray Solutions

As manufacturing technologies evolve, so do vial tray systems. Innovations such as smart trays with embedded sensors and advanced materials are emerging to further enhance efficiency and traceability.

We encourage ongoing evaluation of vial tray technologies to stay ahead in a competitive industry. By partnering with industry leaders and leveraging cutting-edge solutions, we can continue to optimize manufacturing processes and deliver high-quality pharmaceutical products worldwide.

For those interested in exploring high-quality vial tray options, we recommend reviewing the offerings available at Hurst Corporation, a trusted leader in pharmaceutical manufacturing solutions.

By focusing on efficient vial tray systems, we position ourselves to meet the demanding standards of pharmaceutical and biotech manufacturing. Through careful selection, integration, and continuous improvement, these systems become a cornerstone of operational excellence.

Comments